Main Equipment

■ Product Description

The color coating line signifies a process designed to put color coatings on the both surface of an aimed metal strip according to the requirement from customers in steel market. This line consists of entry & exit section, pre-treatment section, coating section, electrical & control equipment and common facilities.

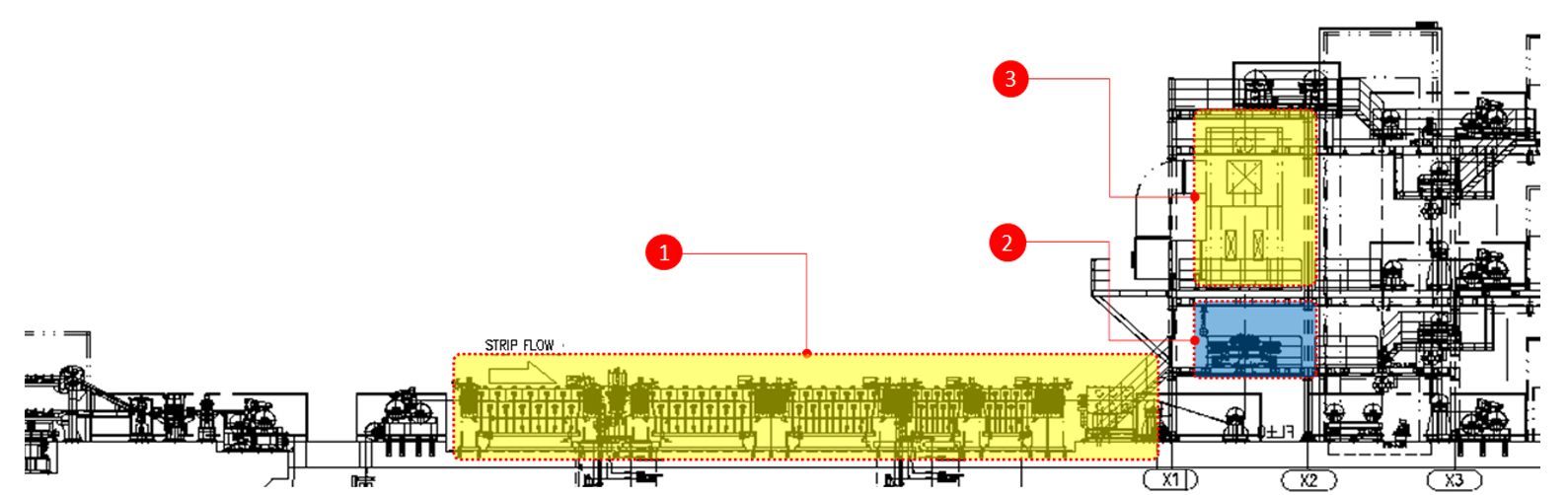

■ Overall Drawing

① Entry Section ② Pre-Treatment Section ③ Coating Section ④ Exit Section ※ R.T.O(Regenerative Thermal Oxidizer)

■ Main Parts Details

Cleaning System

■ Product Description

The residuals on the surface of the incoming coil are then cleaned in a cleaning unit by hot alkali spraying combined with brush scrubbing that typically uses an alkaline liquid as a cleaning chemical, Cleaned coils are rinsed using water in the cascade rinse units and Blown-off by cold air or dried by hot air.

■ Overall Drawing

① Cleaning Zone (Degreasing / Brush / Hot water Rinse Tank Unit) ② Chemical Coater ③ Chemical Dryer

■ Main Parts Details

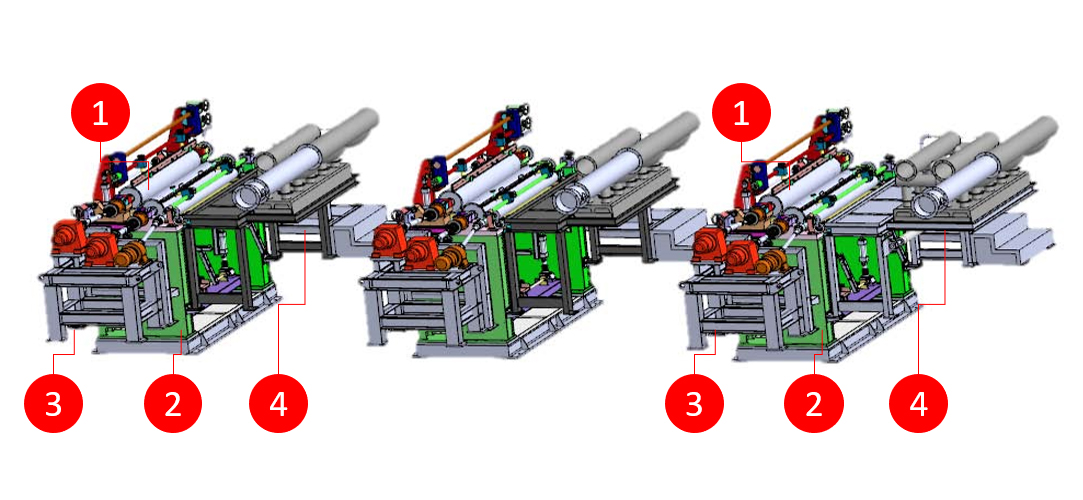

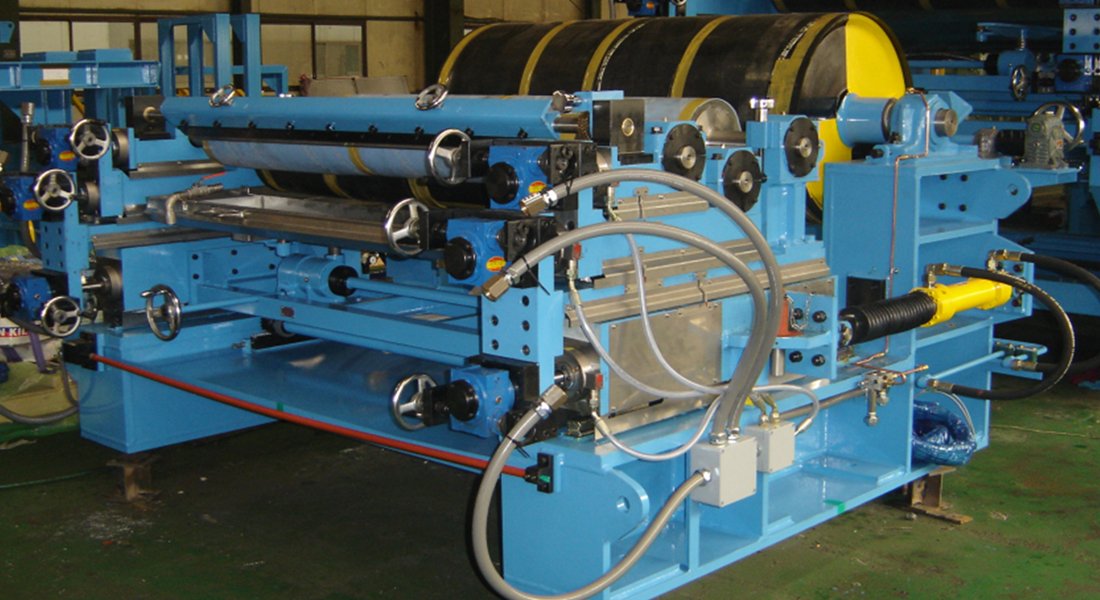

Coater

■ Product Description

The coating machine is designed for precise coating application to both sides of the passing strip by forward or reverse roller coating methods.

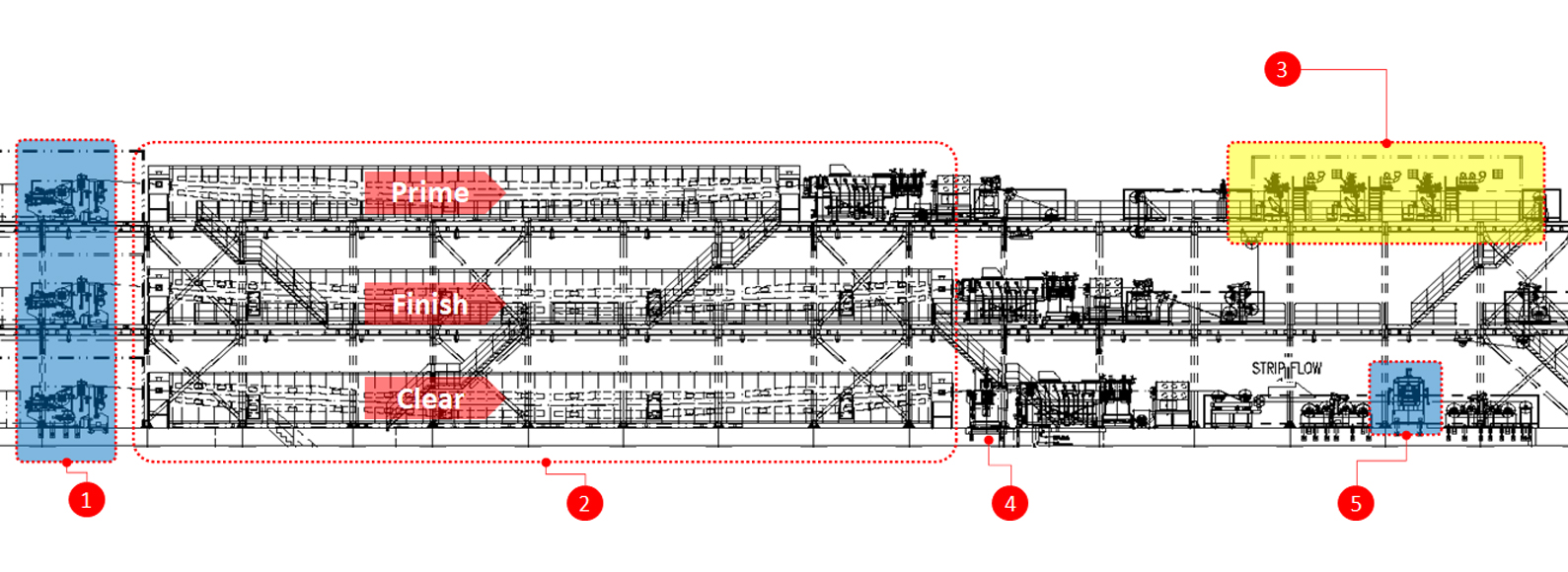

■ Overall Drawing

① Prime / Finish / Clear Coater ② Prime / Finish / Clear Oven ③ Printer (3-color) ④ Laminator ⑤ Tension Leveler

■ Main Parts Details

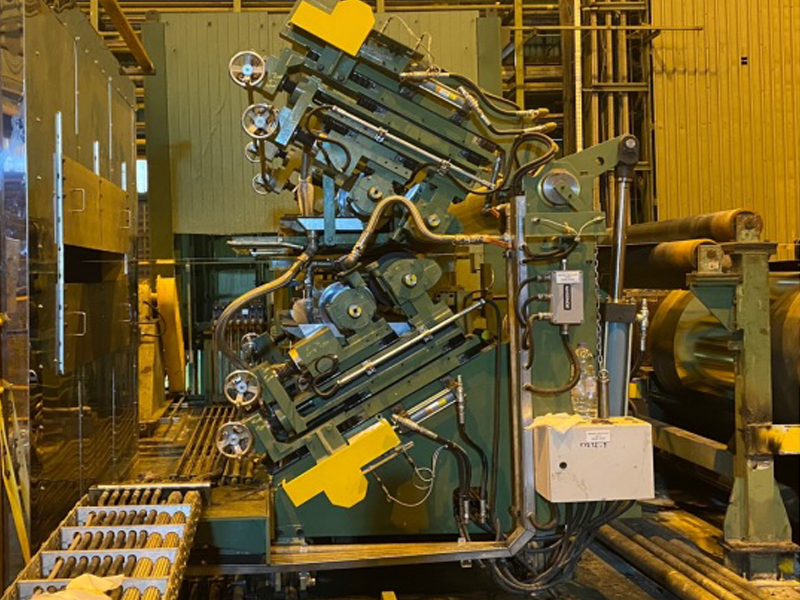

Printer

■ Product Description

The printer is a high class printing equipment which applies the gravure offset printing type to print the pattern on the steel plate. We customize a wide range of patterns and colors such as wood, stone and metal patterns to fulfil each customer's needs.

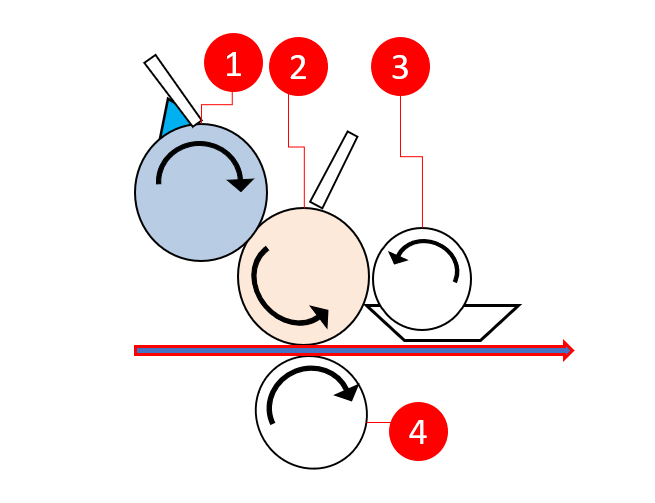

■ Roll Arrangement

Roll Arrangement

① : Pattern Roll (Gravure Roll)

② : Off-set Roll (Applicator Roll or Coating Roll)

③ : Washing Roll

④ : Back-up Roll

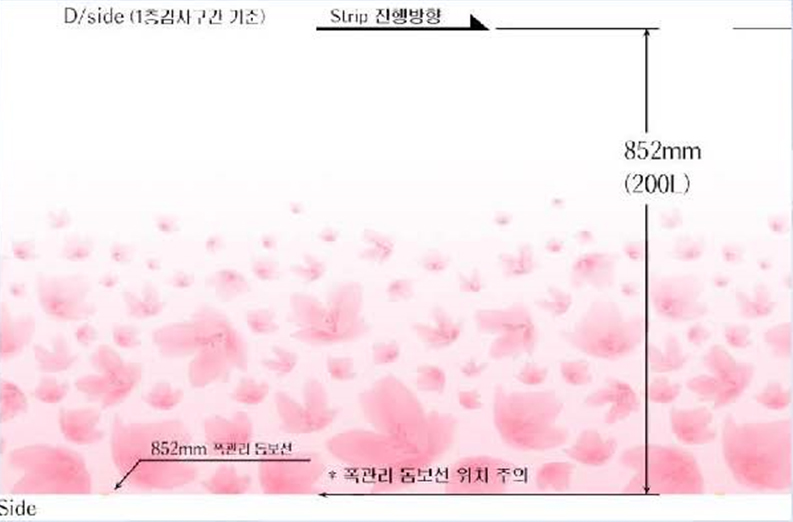

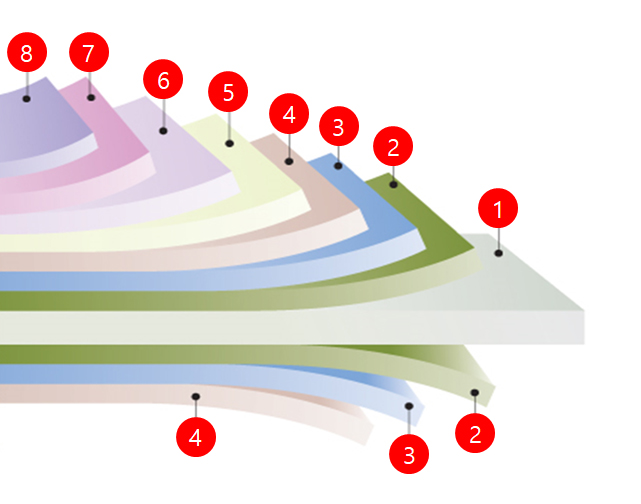

■ Cross Section of the Product

Cross Section of the Product

① : Base Metal

② : Plating Layer (Zn, AL, 55% AL+Zn)

③ : Pre-treatment (Chrome Coating)

④ : Primer Coating

⑤ : Base Coating

⑥ : Ink Printing

⑦ : Clear Coating

⑧ : Protector Film

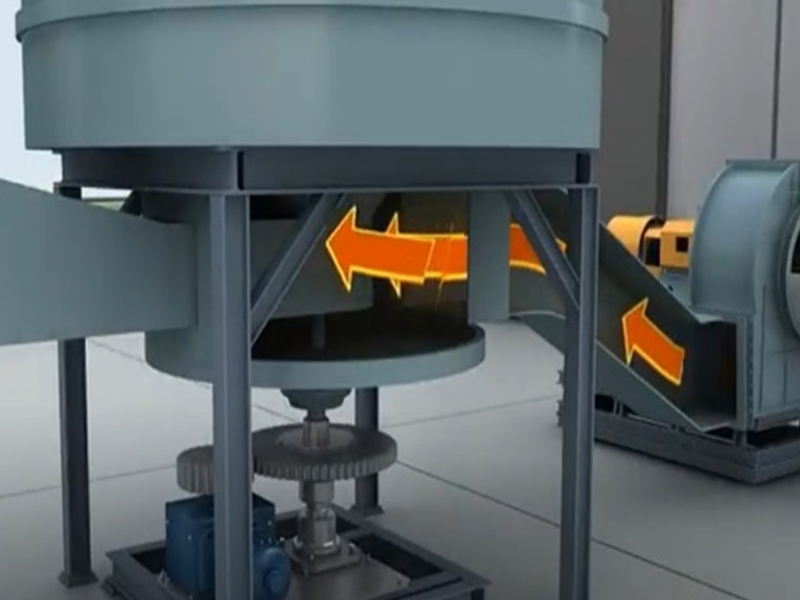

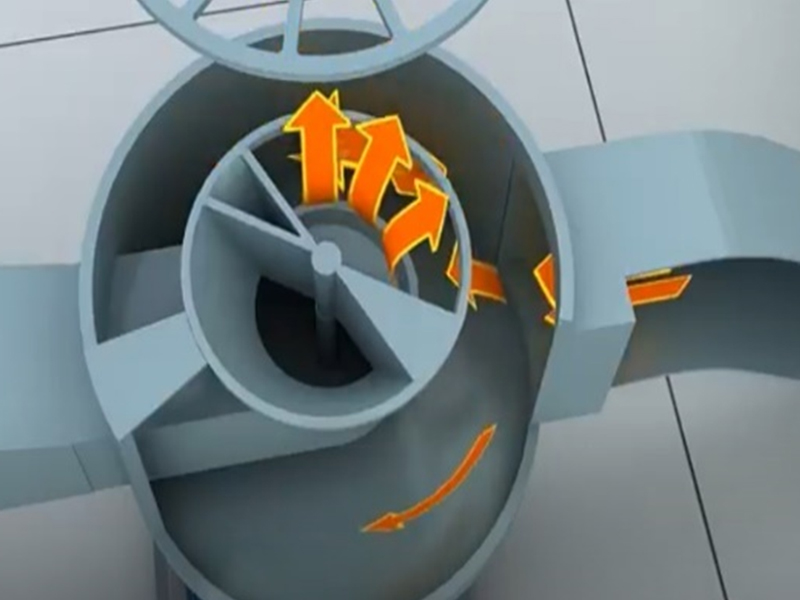

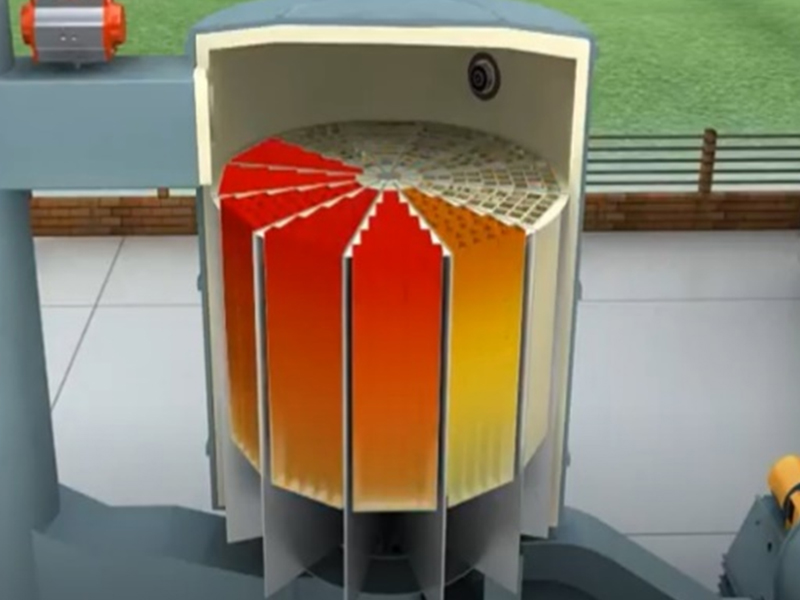

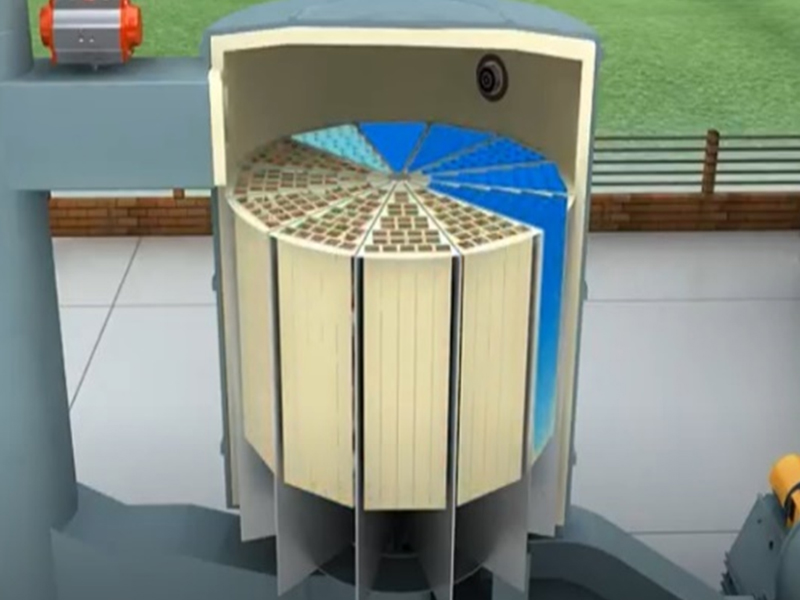

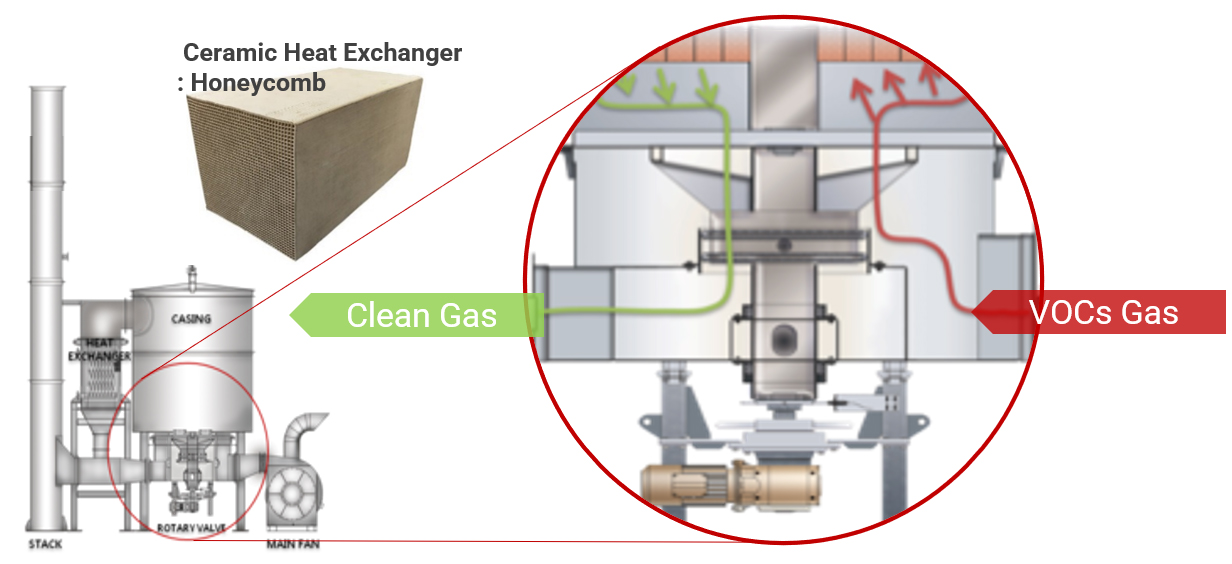

RTO

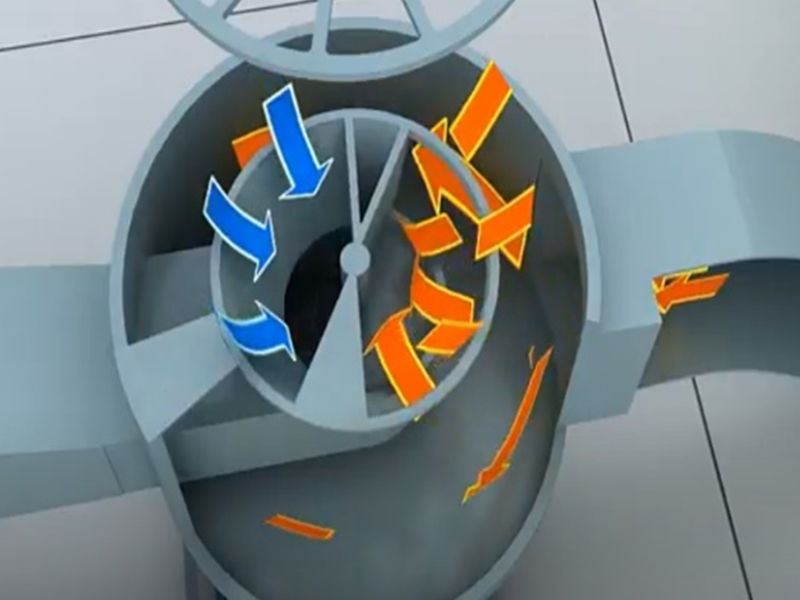

■ Product Description

R.T.O (Regenerative Thermal Oxidizer) is a facility for the removing of the VOCs through a burn-up process at the temperature of 800°C.

The consumption of utility gas is minimized by using the energy of heat more than 95% when the VOCs are burnt by heat exchanging materials.

■ Main Parts Details