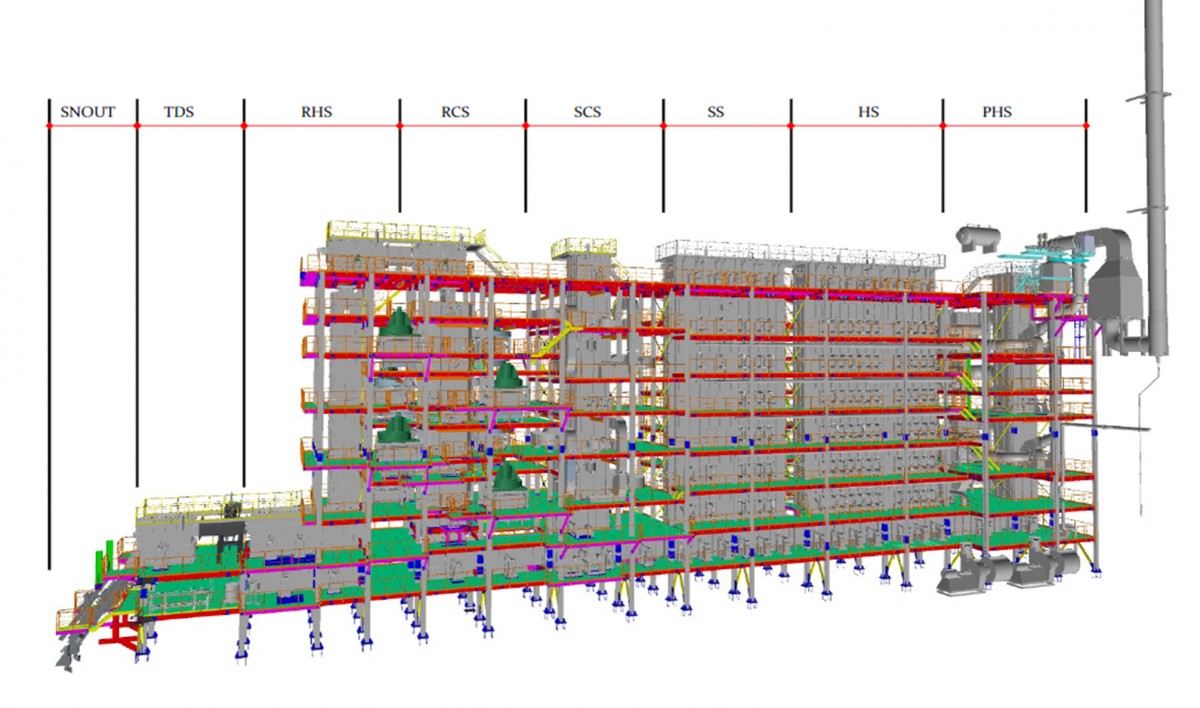

CGL (Continuous Galvanizing Line)_Furnace

Item discription

MJE, with rich technology and experience, have proposed to provide the Furnace of CGL with highly efficient equipment and complementary services including design and supervision for manufacturing, erection, commissioning, and test runs.

New technologies for quality improvement, energy saving, less public nuisance, labor saving, maintenance free and safety are positively adopted to ensure the safe and long term service. Uniform cooling is obtained by special cooling units allowing gas flow adjustment crosswise in several zones to perform strip temperature homogeneity. The cooling is performed by a first slow cooling section and a rapid/slow cooling section under high content H2 protection atmosphere (5 % up to 40 % H2).

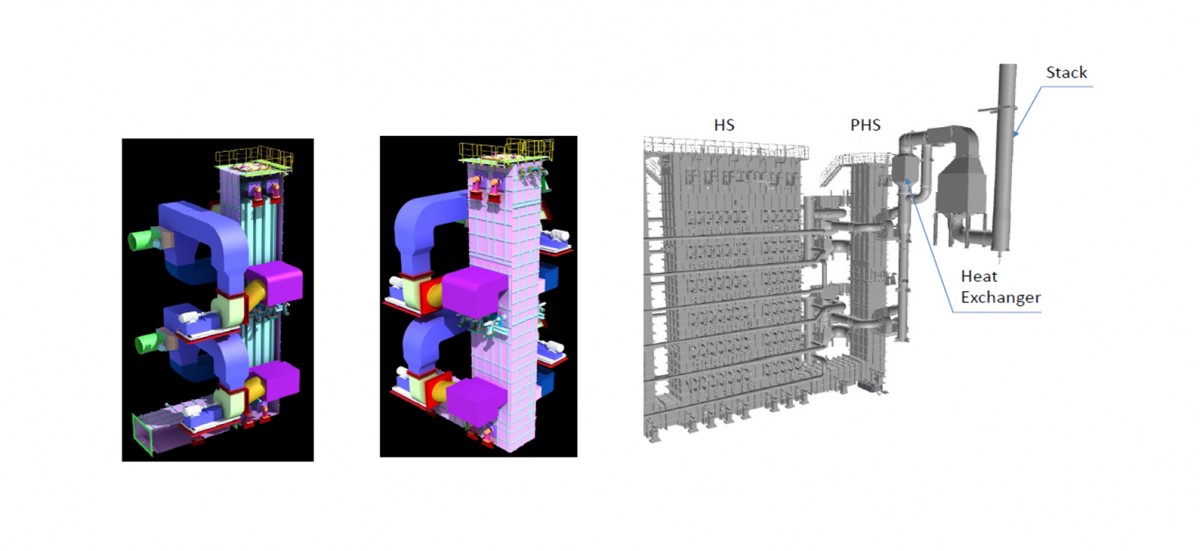

These Furnaces can be of different configuration to suit process requirement. Some of the widely used furnace configurations include

- All Horizontal Configuration

- All Vertical Configuration

- L Shaped Furnace

Key Feature

Heat Recovery by PHS

- Convection Heating By Exchange With The Waste Exhaust Gas

- Waste Gas Cooled From High Temp. Down To Low Temp.

- Strip Pre Heat